Repairing a broken product instead of replacing or disposing of it is full of benefits for the user, the manufacturer and the environment. But repairing a product without also determining why the product failed in the first place essentially condemns the product for future failure. Instead, leveraging failure data to uncover the root cause of the problem is key to preventing future downtime and extending the product’s lifetime — a core goal for outsourced repair service providers.

Engaging a depot repair service provider who doesn’t have the technical chops to do root cause and failure analysis at the board level can feel a lot like going down the rabbit hole, where all possible paths are equally valid and getting to the bottom of things is an exercise in absurdity, much like “Alice’s Adventures in Wonderland.” Even though the product gets fixed, the story behind the failure remains shrouded in mystery.

While mysteries are great for fiction, original equipment manufacturers (OEMs) live in a decidedly non-fiction world where a lack of information can have lasting consequences for their brand reputation and customer experience. The plot should never thicken. An outsourced depot repair service partner’s expert — and entirely rational — approach to failure data and root cause analysis not only ensures that products are repaired quickly and efficiently, but also gives OEMs invaluable access to unbiased feedback that enables them to make informed decisions about precisely where to go next.

Why Do Components or Products Fail?

Even those who pride themselves on quality and innovation — and what OEM doesn’t? — understand that when it comes to technology, something will fail at some point. That’s just reality, whether a product is on the cusp of cutting-edge or nearing its end of life. For OEMs, understanding why and how often products and parts fail is step one on the road to preventing recurrence. Comprehensive, unbiased root cause analysis unearths vital information that OEMs can use to improve designs, reduce failure rates and increase product longevity — all of which make for more satisfied customers.

Technical malfunctions can’t always be laid at the feet of hardware, software or operating systems. It takes an experienced technician to assess the full breadth of functions and conditions that may be at fault. Typically, product failure falls into six categories:

-

A part breaks: There are any number of reasons a component may fail, from adverse environmental conditions and material wear to physical impact and problems with packaging. Poorly manufactured parts can fail prematurely, as can those procured via an unauthorized gray-market provider.

-

Packaging leaves room for error: Although meant to protect what’s inside, inferior packaging plays a huge role in the failure of new parts. Cracks are irresistible entry points for dust motes and water molecules, either of which can short-circuit electronics. Smushed packaging can damage wiring. Materials unable to withstand potential environmental factors along the transportation journey are repairs waiting to happen.

-

There’s a manufacturing defect: This often comes down to the quality of the solder joints. Electrical connections can run through slapdash soldering, but a solid connection requires more attention to detail. Do it wrong and the slightest shock, vibration or hot/cold temperature cycle can cause a shakily assembled board to fail.

-

Initial installation was not done correctly: Root cause analysis can help determine whether a product or part was installed to OEM specifications. Careless installation may be the result of a technician either not paying attention or not having the skill set necessary for proper installation. Installation that routinely goes awry may be due to inaccurate documentation or inadequate training.

-

Design doesn’t account for operating conditions: Technology is a complex beast, with myriad components comprising a finished product. Each of those parts comes with ideal operating conditions, and the limits of their operating parameters are assessed during the design phase. Functionality testing in real-world operating conditions should be done during manufacturing tests. But sometimes the trains don’t meet.

-

There are influential external factors: Technology products are bombarded with threats — and not just the cyber kind. Voltage spikes and mechanical shocks can wreak havoc on electronic components. Liquids can kill them, as can dust bunnies blocking their vents. Leaking batteries and electrolytic caps aren’t friendly, either.

The Value of Failure Data and Root Cause Analysis for OEMs

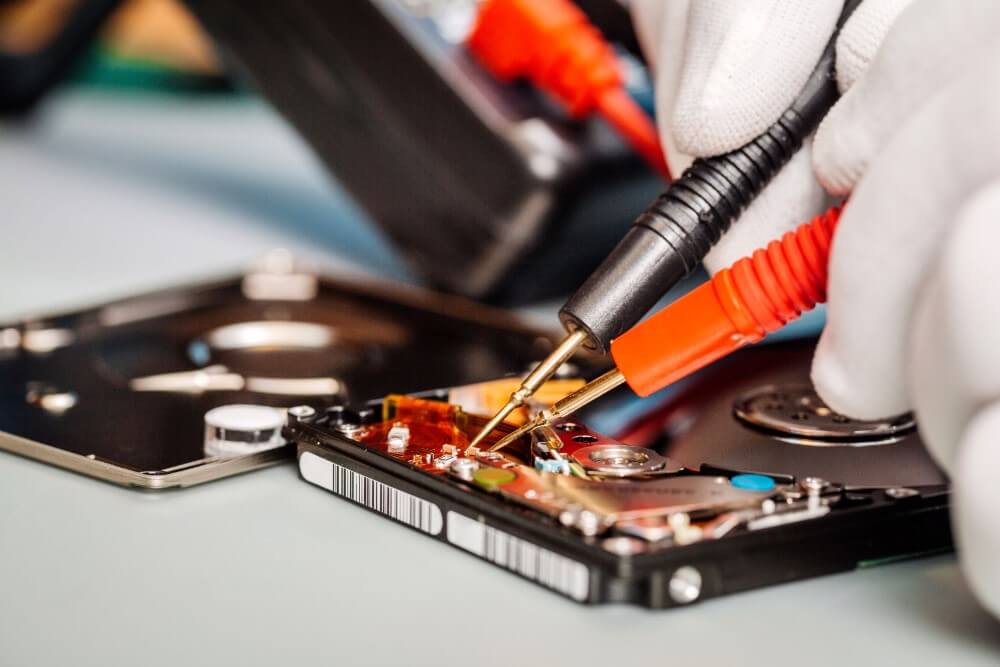

Data is the key to improving product quality. Error logs are a good place to start, but an analytically minded depot repair service partner will go well beyond the obvious, diving into parts manufacturing processes, system design, component integration, environmental conditions, installation errors, user behaviors and other factors that can contribute to a product reaching its breaking point. In that failure data is where you start asking “why?” to find the root cause and gain a fuller picture of how the product is being designed, manufactured, shipped and used by customers.

Root cause analysis can help uncover the answers to questions like:

- Are failures caused by an original manufacturing defect or a core design flaw?

- Is the entire install base affected or just a few components?

- Have key parts reached the end of their useful life? Can they be easily replaced?

- Is the product getting damaged during shipping due to insufficient packaging or mishandling?

- Is product misuse or the operating environment (or both) impacting performance?

Delving into the failure data to conduct root cause analysis can help gauge the potential growth of the problem and find solutions. Frequently, there is a large return on investment, too. But it takes extra effort and resources to dig through the data and follow up with targeted activities to prevent future failure, which is why many OEMs rely on outsourced repair service partners. They will “teach you to fish,” as the parable goes, by providing the data and actionable insights you need to keep parts from failing in the future (rather than just “giving you the fish” by putting a repaired unit back in market with no follow-up).

If the ability to leverage insights based on failure data and root cause analysis is important to you, look for a depot repair partner who:

- Deploys systems that gather operational data as a matter of course, then uses repair data analytics to spot trends impacting product viability

- Refines and optimizes test automation codes routinely so the technical data needed to improve products or bring them back online is always at the ready

- Creates customized tests for expert troubleshooting, customer support and manufacturing feedback

- Has the expertise for product-specific root cause analysis to provide deeper technical insights that can be used to improve designs, reduce costs and make decisions about when it’s time to upgrade or update technology

- Provides real-time visibility into every stage of the repair process, keeping customers informed and fostering trust and transparency

- Identifies trends and patterns by analyzing the data to pinpoint frequently failing components and proactively address equipment weaknesses

- Optimizes logistics and inventory management with efficient equipment tracking to ensure optimal stocking levels, expedite repairs and prevent delays

An expert depot repair services partner can also provide unbiased guidance when it comes to navigating possible causes of failure between an OEM, original device manufacturer, contract manufacturer, supply chain partner and other stakeholders — all of whom may have a hand in a product’s design and performance. Most end customers aren’t concerned with who’s to blame for parts they can’t see, but they’ll be quick to judge the company whose logo is on the product. Unbiased analysis ensures that all relevant parties are informed and that the costs of repairs are assigned to the responsible party, too.

How to Transform Your Business With an Unbiased Depot Repair Partner

Product repairs can make or break the customer experience. Unbiased root cause and failure analysis can help OEMs expedite repairs, improve product designs and minimize future failures — all of which contributes to the circular economy. The right outsourcing partner provides thorough, clearheaded logic to help you make sense of even the most maddening product failures — an OEM’s personal Cheshire Cat, if you will, (minus the agent of chaos thing, of course).

To learn more about rounding out your repair service strategy to embrace failure data, root cause analysis, sustainability and a seamless customer experience, download the eBook, “The Key Spokes of a Full-Circle Repair Strategy.”

About the Author

Ken Ueltzen is a Sales Leader within the repair services organization of Shyft Global Services. His professional experience spans more than 40 years, including key roles in sales and marketing, business development and strategy, manufacturing operations and engineering. He works closely with service delivery experts in Shyft’s state-of-the-art Roseville, California facility, which is home to a wide range of depot repair service capabilities.

Ken Ueltzen is a Sales Leader within the repair services organization of Shyft Global Services. His professional experience spans more than 40 years, including key roles in sales and marketing, business development and strategy, manufacturing operations and engineering. He works closely with service delivery experts in Shyft’s state-of-the-art Roseville, California facility, which is home to a wide range of depot repair service capabilities.