As sustainability takes on greater urgency, original equipment manufacturers (OEMs) are taking a fresh look at what happens after their technology products enter the market — especially as they approach end of life. The circular economy has opened profitable, reputation-enhancing opportunities downstream from the initial manufacture and sale of the product that are good for the planet, your reputation and your bottom line.

What Is a Linear Economy Vs. a Circular Economy?

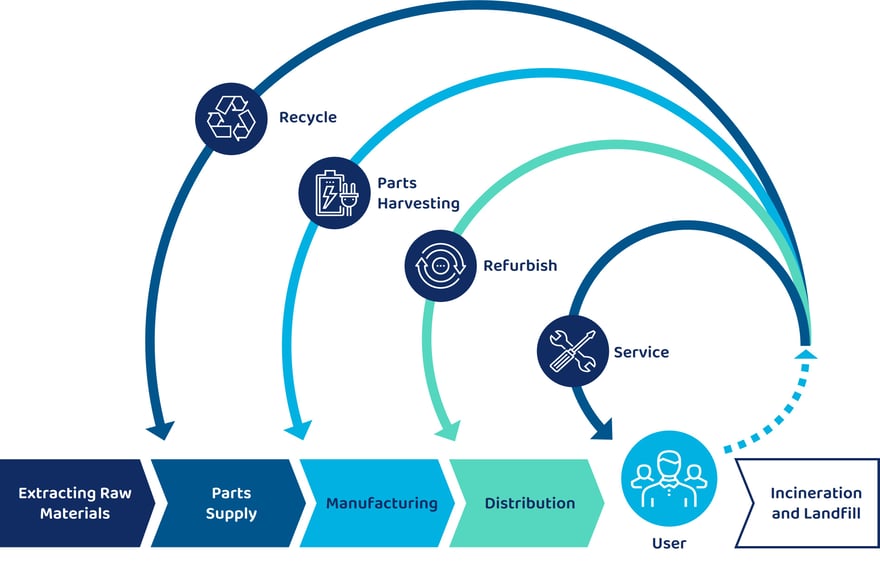

Often called a “take-make-waste” model, a linear economy moves from raw material extraction to product manufacturing to never-to-be-used-again trash that ends up in landfills and adds to the growing e-waste crisis. A circular economy, on the other hand, keeps materials in use for as long as possible to limit pollution, reduce waste and restore natural ecosystems. In a circular economy, innovation takes on new meaning — as in, how can products be better designed to reduce the environmental impact of the production process and promote sustainable consumption?

How a Circular Economy Works

The circular economy is particularly suited to the technology sector, as the raw materials required for manufacturing are oftentimes reusable or recyclable when recaptured. A circular economy starts with the product design itself and is based on three principles:

1. Create Less Waste and Pollution

A circular economy requires products to be designed with sustainability in mind. That can take many avenues. Product designers can make them more durable, reusable, repairable or recyclable. They can eliminate the use of toxic materials or non-renewable resources. They can diminish the waste produced during manufacturing. They can suggest modifications to the production process or the supply chain that moderate emissions.2. Reuse and Recycle All You Can

From the first ideation, technology designers in a circular economy are thinking about how to keep the materials and components that comprise their products in use for as long as possible. What makes them easier to repair? To recycle? How can you repurpose components and reuse raw materials? Thoughtful, challenging questions lead to impactful decisions and strategies that preserve precious resources, decrease e-waste and lower planet-warming carbon emissions.3. Sustain and Restore Ecosystems

A circular economy proposes that economic activity — the production and consumption of technology products, in this case — should not degrade the world’s irreplaceable ecosystems. Using finite resources in a sustainable way and restoring landscapes and biodiversity after raw materials are removed become part of the equation.How a Circular Economy Contributes to Sustainability

By keeping resources in use longer, eliminating e-waste and reducing pollution tied to manufacturing and the supply chain, the circular economy model helps create a more sustainable and resilient system that supports environmental goals. It is the classic “doing good to do well” model. Building sustainability into manufacturing maximizes the value — economic and otherwise — of each product. In addition to the three principles covered in the previous section, a circular economy contributes to sustainability by stimulating design thinking well beyond the initial use of the product itself. It fosters innovation throughout the full technology lifecycle, placing a premium on environmentally sound decisions that are prescient, popular and profitable. For example, the ability to reclaim and repurpose components and raw materials can lower the cost of manufacturing new products significantly.

In addition to the three principles covered in the previous section, a circular economy contributes to sustainability by stimulating design thinking well beyond the initial use of the product itself. It fosters innovation throughout the full technology lifecycle, placing a premium on environmentally sound decisions that are prescient, popular and profitable. For example, the ability to reclaim and repurpose components and raw materials can lower the cost of manufacturing new products significantly.How to Achieve a Circular Economy

Today, “doing good to do well” is an accepted — and in many cases sought after — business practice. OEMs can benefit financially by incorporating environmental responsibility into their operations through a comprehensive forward and reverse logistics solution that considers every step of the product lifecycle. Many companies are already integrating sustainable practices into their strategies to extend product lifecycles, capture new value and enhance long-term success — but knowing just how to do so can be a barrier to overcome.Building expertise and infrastructure in-house and outsourcing to service partners are equally viable ways for technology companies to close the loop on a circular economy. For instance, you may already use returnable or recyclable materials in your product packaging, or you may offer extended warranties, buy-back and trade-in programs and other environmentally responsible capabilities yourself. Or, you may partner with logistics and repair service experts who understand how to properly repair, decommission, repurpose, recycle or (as a last resort) dispose of unwanted IT equipment in a safe, compliant and environmentally responsible way. Or you may outsource non-core competencies entirely to a like-minded, sustainably driven IT lifecycle services management partner that enables you to offer more environmentally friendly capabilities to more customers in more parts of the world.

Regardless of which method (or combination of methods) you implement, sustainability in technology manufacturing is accelerating as customers, partners and companies themselves put a premium on environmental responsibility. Participating in the circular economy enables you to embrace smart stewardship while reducing costs, opening up new revenue streams and setting your brand apart in an increasingly environmentally conscious world.

To learn more about participating in the circular economy and closing the loop, download the whitepaper, “Your Guide to Actionable Sustainability in IT" today.

About the Author

Bobby Wallace serves as the Vice President of Global Repair Services for Shyft Global Services. He focuses on customer growth and service delivery and oversees the company’s CenterPoint facility in Groveport, Ohio, which encompasses Shyft’s widest range of end-to-end product lifecycle services.

Bobby Wallace serves as the Vice President of Global Repair Services for Shyft Global Services. He focuses on customer growth and service delivery and oversees the company’s CenterPoint facility in Groveport, Ohio, which encompasses Shyft’s widest range of end-to-end product lifecycle services.